Most manufacturing websites fall behind not because teams don’t care, but because they’re built on assumptions that don’t match how digital actually works. That gap quietly erodes trust with new customers.

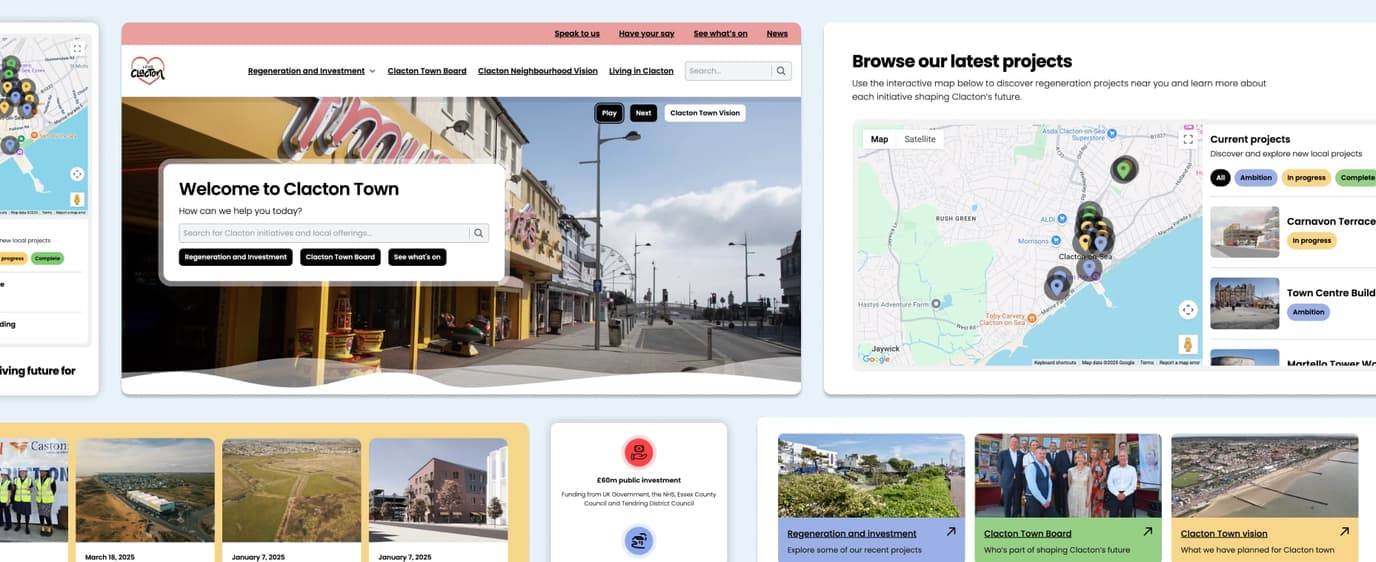

Walk through most manufacturing websites and you’ll notice the same pattern: they look and feel abandoned. Outdated copyright notices, broken links, old social media icons, and content that hasn’t been updated for years.

It’s not because the company doesn’t care. It’s usually because the website isn’t seen as an operational priority. But that mindset is costing businesses more than they realise.

This post breaks down why it happens, what it signals to potential customers, and what manufacturers can do to fix it.

The common signs of an outdated website

Most people can spot an ageing website instantly. The giveaways are usually obvious:

- Copyright dates that predate COVID

- Links pointing to Twitter instead of X

- A news section with “recent” updates from 2023, followed by a jump to 2021 or earlier

- Failing core web vitals: slow, heavy, unstable pages

- Dated or low-quality imagery

- Broken or unreliable functionality

- Poor mobile experience

Each issue alone is minor. Together, they create a narrative that undermines credibility.

Why manufacturing websites fall behind

Manufacturing teams are busy. Operations, production, compliance, supply chain, and customer delivery all take priority. A website feels static and low-risk in comparison.

There are three consistent reasons these sites age quickly:

- No clear ownership

- Marketing might handle messaging. IT might handle hosting. But the website’s structure, content, imagery, and overall health rarely sit squarely with anyone.

- No awareness of how and why the website needs updating

Treating the website like long-life equipment

Manufacturing is full of long lifecycles. Machines last decades and processes change slowly.

The problem is that this mindset doesn’t translate to digital. Websites, content, performance, and user expectations move far faster. While the factory floor evolves predictably, a website can become outdated in a matter of months. When that long-lifecycle thinking spills over into digital assets, companies end up with sites that technically work but silently fall behind in usability, trust, security, and relevance.

Success creates complacency

If the order book is full and relationships are strong, it’s easy to assume the website isn’t part of the sales engine. But prospects who don’t know you will always start online.

The moment a potential customer lands on your website, they look for signals of capability and reliability. When the site is outdated, it unintentionally communicates:

- You don’t maintain your digital presence

- Not much is happening worth sharing

- Attention to detail may be inconsistent

- You could be slow to adapt

- You may not invest in process or technology

These thoughts are rarely conscious, but they affect trust, especially in industries where reliability is critical.

Why this matters more right now

Digital expectations have risen sharply. Competitors are modernising. Buyers research online long before they speak to anyone.

Customers now expect:

- Clear, detailed product information

- Fast, responsive pages on any device

- Up-to-date certifications and case studies

- Easy ways to request quotes or get support

- A sense that the business is active and improving

A website is no longer a digital brochure. It is a credibility checkpoint.

Why minor fixes often aren’t enough

A quick tidy-up can remove the most obvious issues, but many manufacturing websites aren’t suffering from small problems. They suffer from foundations that are no longer fit for purpose.

Typical issues include:

- Old CMS installations with security risks

- Templates that can’t meet accessibility standards

- Heavy, unoptimised pages that fail modern performance requirements

- Brand imagery that no longer represents the business

- Navigation structures built around old product lines or internal silos

In these cases, superficial fixes only mask deeper problems. A rebuild or rebrand is often the most efficient and cost-effective path, especially when the business has changed significantly since the original site was built.

This isn’t about chasing design trends. It’s about aligning the website with what the company has become.

A practical way forward

Manufacturers don’t need glossy, over-designed websites. They need modern, simple, functional ones that reflect how they actually operate.

Most manufacturers benefit from tackling the following first:

- Reviewing whether the current brand and site still represent the business

- Deciding whether a rebuild will save more time and cost than incremental patching

- Updating copy, imagery, and case studies to reflect recent work

- Improving site structure so users can find information quickly

- Prioritising performance, accessibility, and reliability

- Putting a simple maintenance schedule in place

None of this requires a marketing revolution. It requires clarity, ownership, and a willingness to modernise.

In summary

If your website feels like it has been left untouched for years, it’s time to bring it back into the workflow.

Modernising your digital presence isn’t about vanity. It reinforces trust, strengthens sales conversations, and shows pride in the quality of your work. In a market where customers have more choice than ever, those signals matter.